ASQ CCT Certification Prep iOS

Achieve mastery in your ASQ CCT exam preparation with the ASQ CCT Certification Prep app!

This powerful study tool immerses you in a dynamic test preparation environment, featuring a robust collection of practice questions that span all critical areas necessary for achieving Certified Calibration Technician success.

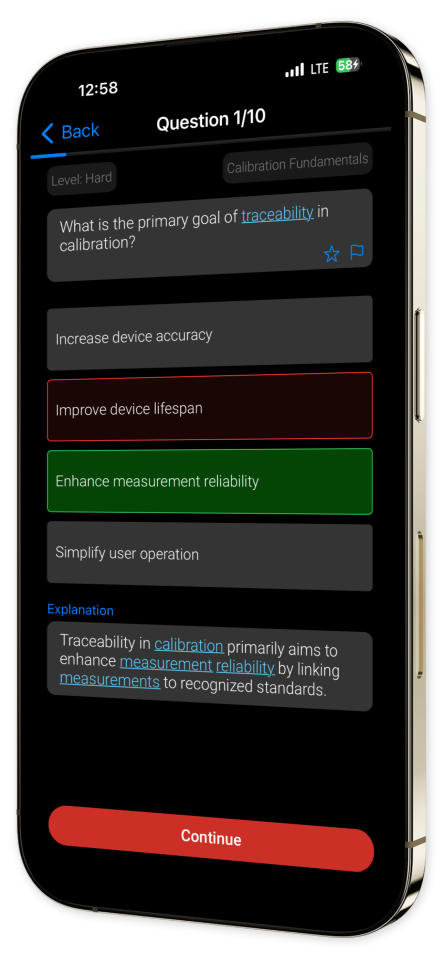

Every question in our extensive repository is accompanied by an insightful explanation, helping you build a deeper understanding and refine your expertise.

Key Features:

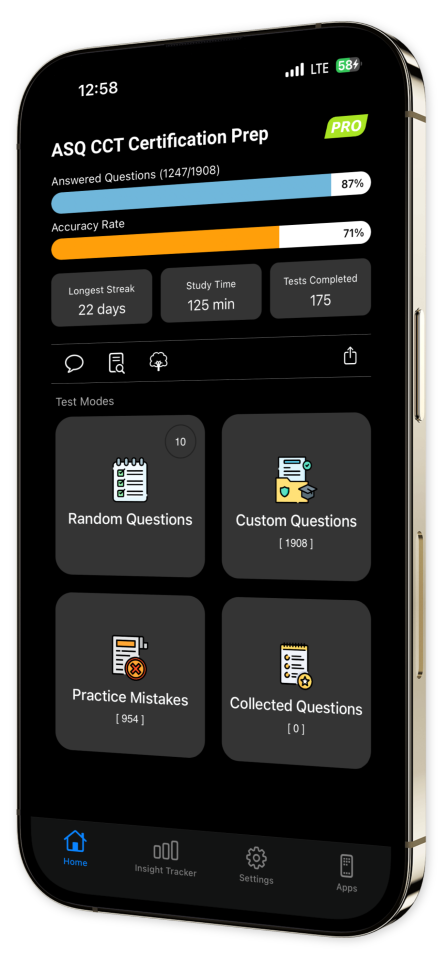

Extensive Question Bank: Delve into hundreds of practice questions that encompass key topics to ensure comprehensive exam readiness.

In-Depth Explanations: Uncover nuanced insights with elaborate rationales for each question, enhancing learning and retention.

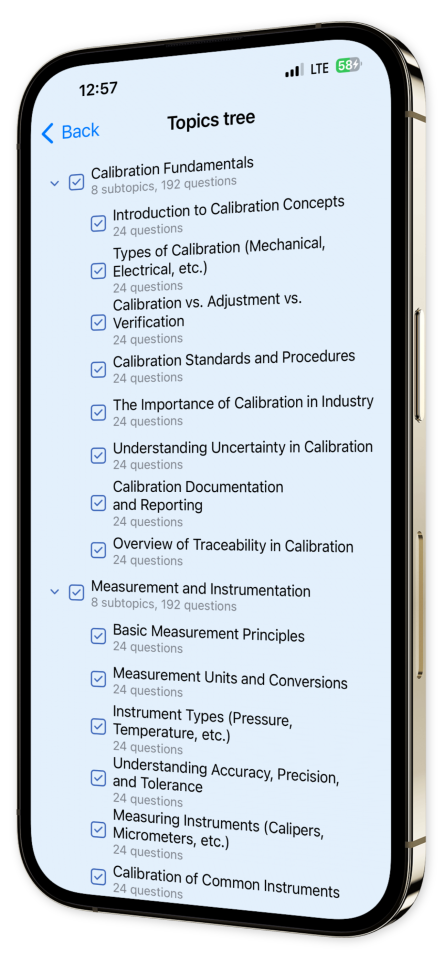

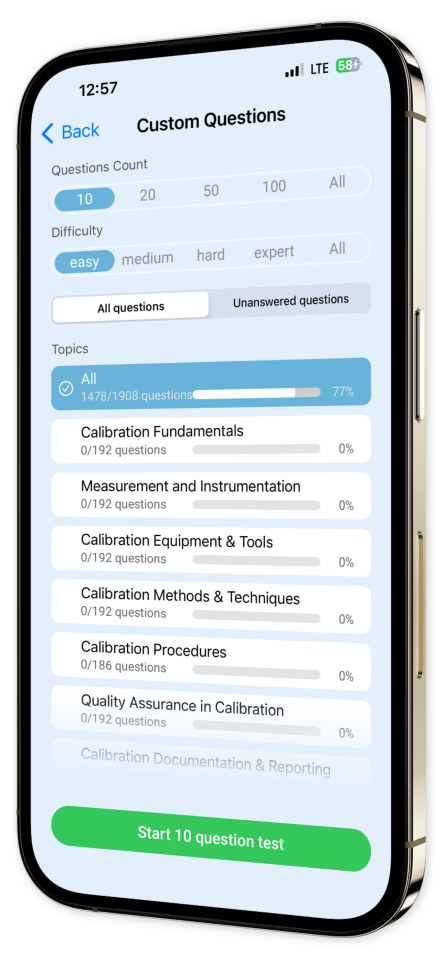

Customizable Quizzes: Craft personalized quizzes by selecting specific topics and question types, allowing focused study on your areas of need.

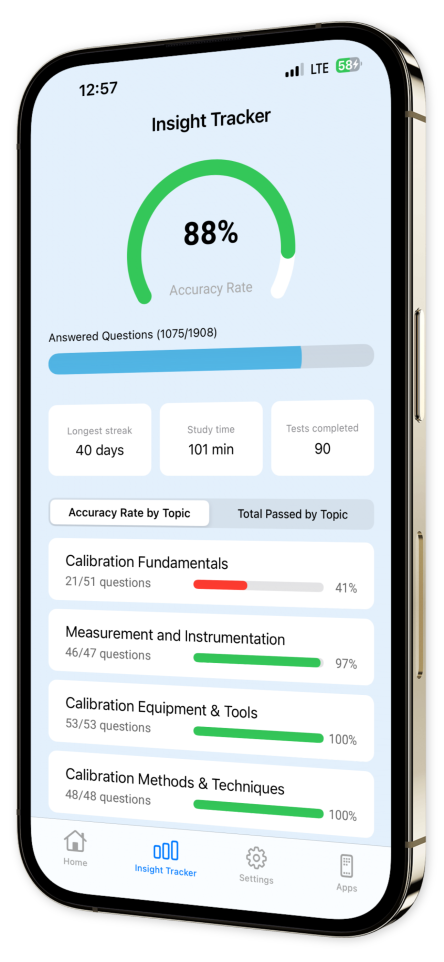

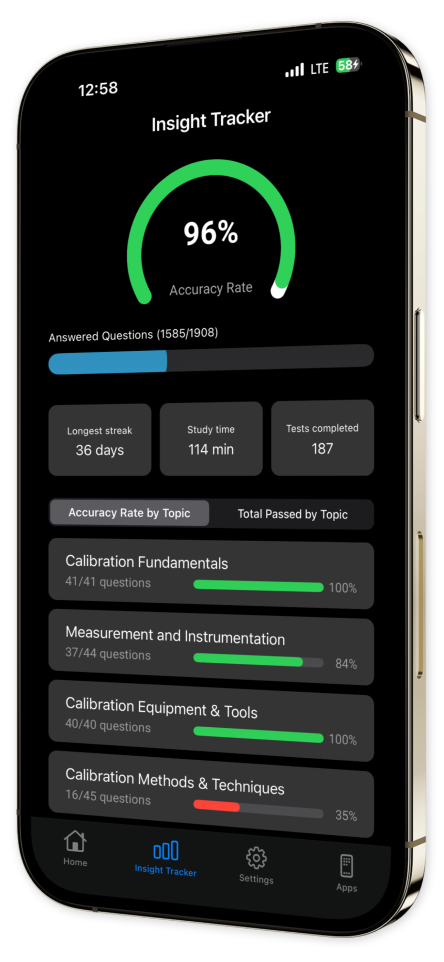

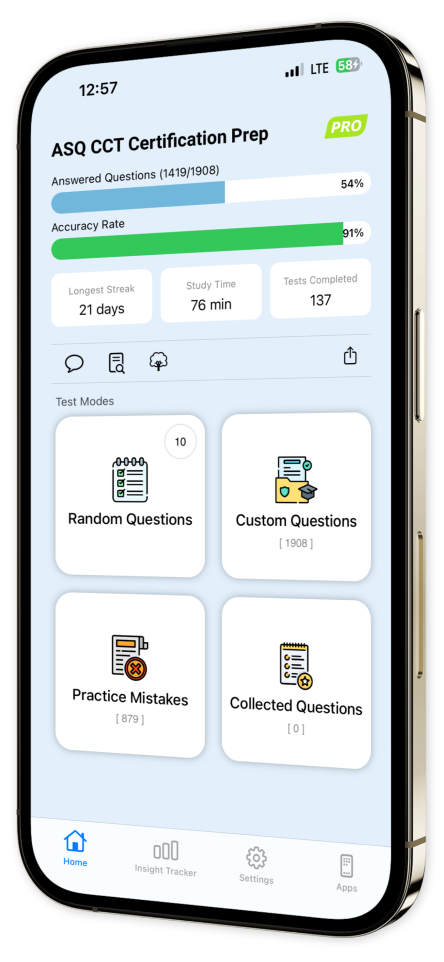

Progress Tracking: Monitor and celebrate your advancement with intuitive progress tracking features that provide clear visibility on your performance.

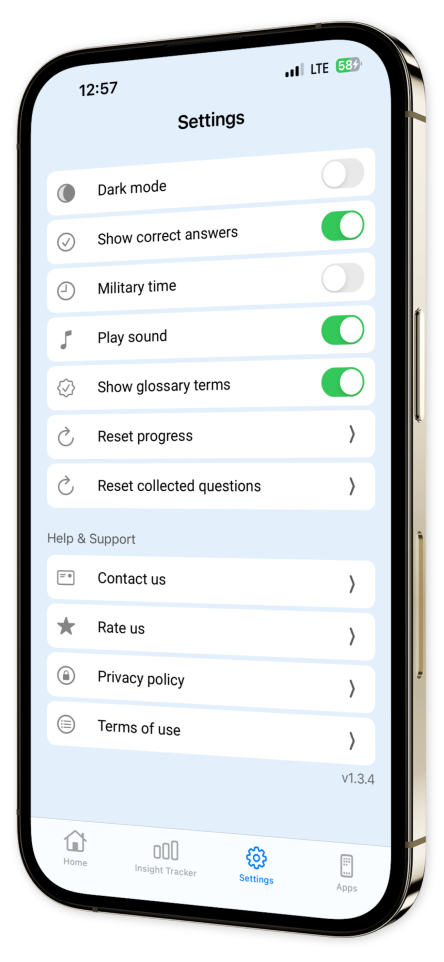

Offline Access: Continue your studies anytime, anywhere, even without an internet connection, making it ideal for studying on the move.

User-Friendly Interface: Navigate with ease thanks to an expertly designed, intuitive interface that facilitates effective learning.

Ready to take your ASQ CCT exam preparation to the next level?

Download the ASQ CCT Certification Prep app today and equip yourself with the tools to excel in your certification journey.

Step into a smarter way of preparing and ensure you're equipped with the knowledge and confidence to succeed.

Content Overview

Explore a variety of topics covered in the app.

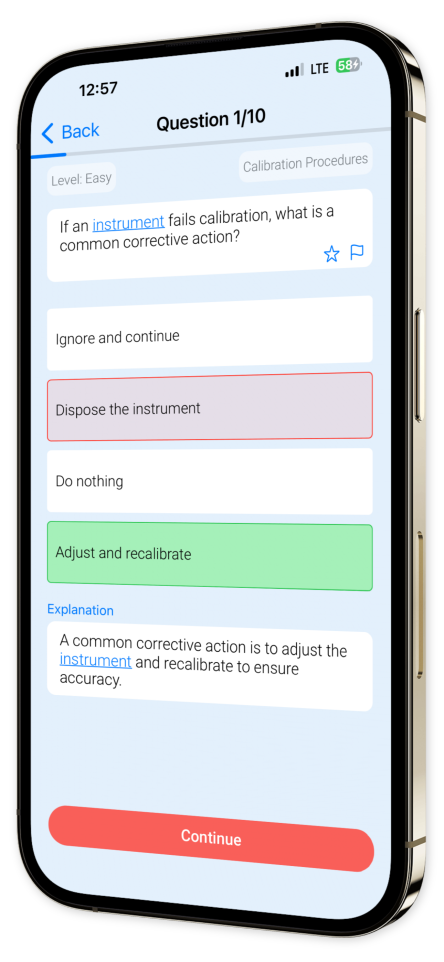

Example questions

Let's look at some sample questions

When calibrating a temperature sensor, the reference standard should be:

More accurate than the sensorThe same size as the sensorCheaper than the sensorUsed less frequently

The reference standard must be more accurate to ensure reliability and effectiveness of calibration, typically at least four times more precise than the device being tested.

Which factor is NOT considered when determining calibration frequency?

Color of the equipmentFrequency of useManufacturer's recommendationsPast performance history

The color of equipment does not influence calibration frequency; it's based on usage, historical performance data, and manufacturer guidance.

What statistical test is best for analyzing calibration linearity?

Chi-squared testANOVAStudent's t-testRegression analysis

Regression analysis assesses the linear relationship between instrument readings and true values, crucial for calibration linearity validation.

Which factor is crucial when selecting a calibration standard?

Cost of calibrationMeasurement accuracy requiredLocation of useColor of the device

The required measurement accuracy is crucial to select an appropriate calibration standard.

For a thermocouple calibration, why must environmental factors be considered?

They influence thermocouple durabilityThey affect reading accuracyThey modify reference voltageThey change metal composition

Environmental factors such as temperature, humidity, and pressure can affect the accuracy of thermocouple readings, necessitating their consideration during calibration.

What is a common frequency for equipment calibration?

DailyMonthlyAnnuallyOnce in a lifetime

Calibration frequency depends on equipment and usage, but annual calibration is a standard practice for many devices to ensure reliability.

Which is affected if calibration is neglected?

Employee moraleMeasurement accuracyOffice aestheticsData storage space

Neglecting calibration affects measurement accuracy, leading to unreliable data and potential process failures.

If a balance has an uncertainty of ±0.1g, what is the likely source of uncertainty?

Instrument's display resolutionAmbient temperature variationCalibration weight qualityOperator's skill level

The uncertainty due to the balance's display resolution often results in small values like ±0.1g, indicating the smallest change displayable.

What key detail is included in a calibration certificate?

Customer feedbackLast calibration dateInventory codePurchase order number

A calibration certificate includes key details such as the last calibration date and other relevant data, ensuring traceability.

Why is traceability important in calibration?

Ensures instrument popularityMaintains advertising strategiesLinks measurements to standardsReduces manufacturing costs

Traceability links measurements back to international standards, providing assurance of accuracy and consistency.